Metering Dosing Pumps

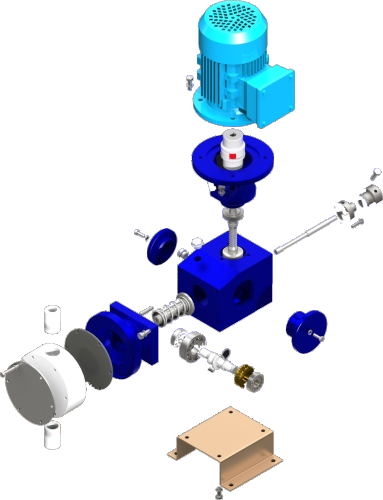

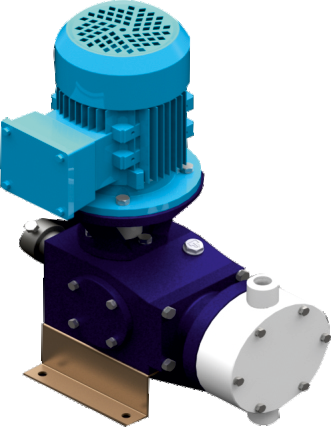

Hidraulic Actuated Diapharagm Pump for chemical processing

- Chemical Processing Applications Involve Regulating Feed Rates. Reactant Feed Applications Require Releasing Chemicals In Real-time Into Reaction Vessels, Typically For Manufacture Or Chemical Synthesis. End-product Processing Uses Metering Pumps To Accurately Dispense Product Into A Mold Or Container. The Chemicals Involved Can Include Virtually Any Chemical Precursor Or End Product.

Our pumps are used for all the applications described above. Kindly send us your valuable inquires so as to give best offer and Look forward for life long association.

Our valued clients can avail from us precision engineered Hydraulic Actuated Diaphragm Pump. Designed to excellence, our Hydraulic Actuated Diaphragm Pump is driven by single Drive And Able To Handle Two Types Of Liquids Simultaneously. We Offer Hydraulic Actuated Diaphragm Pump In Different Specifications To Cater To The Divergent Demands Of The Clients.

Features

- - Waterjet Make Hd Type Diaphragm Gland Less Pumps

- - Leak Free Operation

- - Flow Rates Of 0to 8000 Lph, High Discharge Pressures Of 200 Kg/sq. Cm. Can Be Achieved

- - Steady State Metering Accuracy Of +/- 1% Of Pump Output, At Single Setting Of Stroke From 10%-100%

- - Reproducibility (repeatability) Better Than +/- 1.5% Of Set Point

- - Inbuilt Pressure Relief & Vacuum Valve On The Hydraulic Side To Safeguard System

- - Double Diaphragm With Reputure Indication Also Available

- - Can Easily Handle Most Of The Liquids

- - Simplex And Multiplex Arrangements Of Pumps Available For Universal Use

- - Heating Or Cooling Jackets For Liquid Head Available

- - Pump Model Hyd Mm-i

- - Max (l.p.h.) Capacity - 0 To 8000

- - Pressure (kg. /sq. Cm.) Max200 Liquid Contact Materials (wetted Parts):

- - Ptfe Diaphragm

- - Standards : Aisi 304 And Aisi 316 Raw Material : Monel, Alloy 20, Hast Alloy B, Propylene, Hast Alloy C, Titanium, Gft, Pp. Ptfe And Pvc

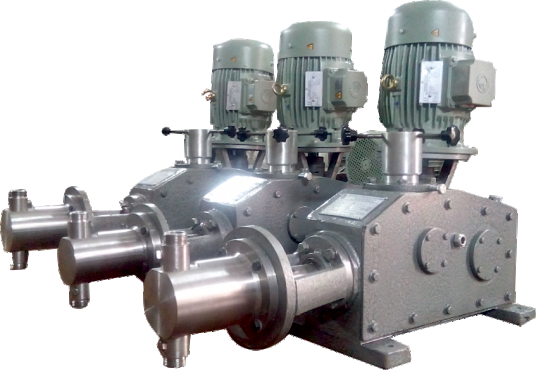

Piston Type Metering Dosing Pump

Piston Pumps Act Similarly To Diaphragm Pumps In That They Mimic Two-cycle Engines. These Pumps Use A Reciprocating Plunger To Move Liquid Through The Unit. They Have A Rigid Piston Assembly, Which Gives Them The Highest Pressure And Accuracy Of Metering Pumps. Since The Piston Slides Against A Cylinder Wall, They Should Generally Not Run Dry. Piston Pumps Can Produce Up To 5,000 Psi And Are Ideal For High-pressure Liquid Chromatography Applications. They Are Generally Used In Chemical Processing, Laboratory Dispensing And Water Treatment Applications.

DIAPHRAGM PUMPS

Diaphragm Pumps Waterjet A Flexible Diaphragm To Displace Liquid With Each Stroke. The Diaphragm Typically Acts Against A Rigid Plate. Its Motion Is Analogous To A Two-stroke Engine. Diaphragm Pumps Deliver Fluid With A High Degree Of Pulsation. Diaphragm Pumps Can Be Solenoid Operated Or Mechanical Geared Drive Motor Or Hydraulically Motor Driven. Diaphragm Pumps Are Used Extensively For Water Treatment Applications.

Mechanical Diaphragm Pumps Have Diaphragms That Move In Response Like Internal Combustion Engines. While They Can Deliver Much Higher Flows And Pressures, They Should Never Be Pumped Against A Dead Head For Fear Of Rupture Of Diaphragm.

Hydraulic Diaphragm Pumps Are Capable Of Higher Flow Rates And Pressures Than Solenoid And Mechanical Units Because They Deliver The Drive Power Force Uniformly To The Diaphragm. However, Due To The Complexity Of Valve And Hydraulic Subsystems, These Pumps Are Expensive.

Mechanical and hydraulic diaphragm pumps are used in water treatment applications where the pressures are high.

Technical Characteristics

| Sr. No | Description | MOC |

|---|---|---|

| 1 | PISTON | EN 8 |

| 2 | LIQUIED HEAD | SS 304, SS316, HASTALLOY, ALLOY 22 PP PVC, PTFE |

| 3 | NON RETURN | SS 304, SS316, HASTALLOY, ALLOY 22 PP PVC, PTFE |

| 4 | SEALING RING | PTFE |

| 5 | GLAND PACKING | PTFE |

| 6 | NRV BALLS | SS, PTFE, GLASS CERAMIC |

Pump Models

| Sr. No | Model | Capacity in LPH |

|---|---|---|

| 1 | WM-10 | 0-50 |

| 2 | WM-15 | 0-100 |

| 3 | WM-20 | 0-150 |

| 4 | WM-25 | 0-200 |

| 5 | WM-30 | 0-300 |

| 6 | WM-40 | 0-500 |

| 7 | WM-50 | 0-1000 |

| 8 | WM-60 | 0-1500 |

| 9 | WM-70 | 0-2000 |

| 10 | WM-80 | 0-3000 |

| 11 | WM-90 | 0-4000 |

| 12 | WM-100 | 0-5000 |

| 13 | WM-110 | 0-6000 |

| 14 | WM-120 | 0-7000 |

| 15 | WM-130 | 0-8000 |